Nyckeltillämpningar av bornitridkeramik i elektrisk framdrivningsteknik och plasmapropeller

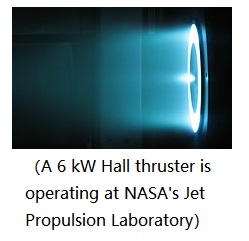

Framdrivningsteknik inom rymdutforskning har alltid ställts inför betydande utmaningar. Traditionella kemiska drivmedel kräver stora transporter mängder bränsle, vilket ökar kostnaderna och begränsar rymdfarkostens uppdragskapacitet. För att övervinna dessa begränsningar har elektrisk framdrivningsteknik kommit fram som ett mer effektivt alternativ. Bland olika elektriska framdrivningsmetoder använder Hall-propellern - en typ av plasmapropeller - ett starkt elektriskt fält för att accelerera joner för exakt attitydkontroll och omloppshöjning. För pålitlig och effektiv elektrisk framdrivningsteknik är det viktigt att välja rätt material för kritiska komponenter.

mängder bränsle, vilket ökar kostnaderna och begränsar rymdfarkostens uppdragskapacitet. För att övervinna dessa begränsningar har elektrisk framdrivningsteknik kommit fram som ett mer effektivt alternativ. Bland olika elektriska framdrivningsmetoder använder Hall-propellern - en typ av plasmapropeller - ett starkt elektriskt fält för att accelerera joner för exakt attitydkontroll och omloppshöjning. För pålitlig och effektiv elektrisk framdrivningsteknik är det viktigt att välja rätt material för kritiska komponenter.

Boron Nitride Keramik: Ett nyckelmaterial för Hall Thrusters

Inom sfären av avancerad keramik spelar Boron Nitride Ceramic en avgörande roll på grund av dess exceptionella egenskaper, vilket gör det till ett idealiskt material för elektrisk framdrivningsteknik och applikationer för rymdutforskning. Som ett konstruktionsmaterial i Hall-propeller och plasmaframdrivningssystem ger det flera fördelar:

1. Högtemperaturmotstånd

En av de viktigaste egenskaperna hos Boron Nitride Ceramic för rymdutforskning är dess exceptionella motståndskraft mot höga temperaturer. Materialet har en hög smältpunkt och en låg termisk expansionskoefficient, vilket säkerställer strukturell stabilitet under extrema temperaturer. Denna egenskap minimerar deformation eller sprickbildning i högtemperaturplasmamiljöer, vilket möjliggör konsekvent och pålitlig dragkraftsgenerering i elektriska framdrivningssystem.

2. Överlägsen elektrisk isolering

Boron Nitride Ceramic är en utmärkt elektrisk isolator som förhindrar oönskad strömledning i Hall-propeller. Joniserings- och accelerationsprocesserna i plasmapropeller kräver material med hög elektrisk isolering för att förhindra strömläckage och säkerställa systemstabilitet. Genom att använda Boron Nitride Ceramic bibehåller elektriska framdrivningssystem optimal effektivitet och tillförlitlighet i utrymmets vakuum.

3.Exceptionell korrosions- och plasmaerosionsbeständighet

Rymdmiljöer utsätter material för jonförstoftning och kemisk korrosion. Boron Nitride Ceramic for Space Exploration erbjuder anmärkningsvärt motstånd mot dessa svåra förhållanden och förhindrar nedbrytning orsakad av långvarig exponering för joniserade gaser och extrema driftsmiljöer. Denna hållbarhet förlänger livslängden avsevärt för komponenter i elektriska framdrivningstekniker, vilket minskar underhållskraven och operativa risker.

Avancerar rymdutforskningen med Boron Nitride Ceramic

Användningen av Boron Nitride Ceramic i elektrisk framdrivningsteknik är avgörande för prestandan och livslängden hos Hall-propeller och andra plasmabaserade framdrivningssystem. Dess överlägsna högtemperaturbeständighet, enastående elektrisk isolering och utmärkta korrosionsbeständighet gör det till ett föredraget material för applikationer för rymdutforskning.

När avancerad keramik fortsätter att utvecklas kommer Boron Nitride Ceramic för rymdutforskning att spela en allt viktigare roll för att möjliggöra utökade uppdragslängder, förbättra rymdfarkosternas effektivitet och stödja utforskning av rymden på djupet. Med sina kritiska egenskaper säkerställer Boron Nitride Ceramic ett tillförlitligt och effektivt framdrivningssystem, driver innovation inom elektrisk framdrivningsteknik och utvidgar gränserna för mänskligt rymdutforskning.

XIAMEN MASCERA TECHNOLOGY CO., LTD. är en ansedd och pålitlig leverantör specialiserad på tillverkning och försäljning av tekniska keramiska delar. Vi tillhandahåller skräddarsydd produktion och högprecisionsbearbetning för en bred serie av högpresterande keramiska material inklusivealuminiumoxid keramik, zirkonium keramik,kiselnitrid,kiselkarbid,bornitrid, aluminiumnitridochbearbetbar glaskeramik. För närvarande kan våra keramiska delar hittas i många industrier som mekanisk, kemisk, medicinsk, halvledare, fordon, elektronik, metallurgi etc. Vårt uppdrag är att tillhandahålla keramiska delar av bästa kvalitet för globala användare och det är ett stort nöje att se våra keramiska delar fungera effektivt i kundernas specifika applikationer. Vi kan samarbeta om både prototyp och massproduktion, välkommen att kontakta oss om du har önskemål.